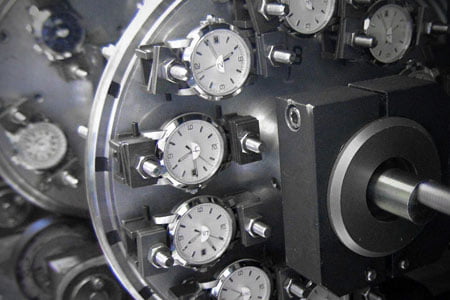

Technical & aesthetic criteria

The movement must have a finish of exclusive aesthetic quality

Specifications define the level of finish required for the movement and its decoration. These were discussed and approved by a group of experts that united specialists in research, teaching and production. Compliance with them takes the form of a preliminary examination at the stage when the piece consists of a kit of parts. The general principles are notably:

Materials:

Metal, technical ceramics, precious or avant-garde materials must be used.

Exclusive finishing:

A decoration must necessarily be visible on the maximum thickness of the plate or on the visible part of the bridge, as well as in the main recesses. No visible burrs must be present and the functional zones of the steel parts must be polished. The shaped parts must be bevelled, polished, and where technically possible have lines drawn out with file strokes.

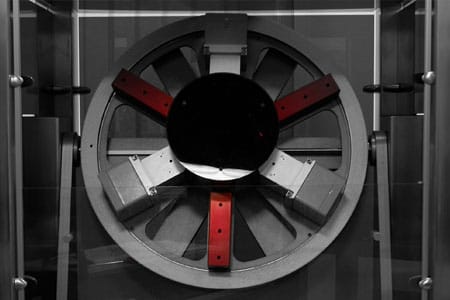

Means:

Manufacturing procedures for decorations may be eithe mechanical or manual. Operations carried out in bulk only are not tolerated.